-

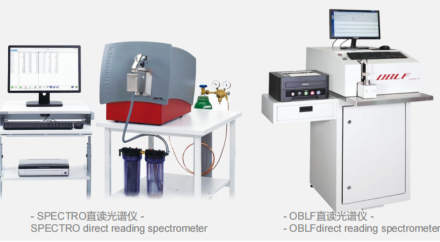

Test Equipment

To auickly and accurately detect and adjust chemical composition, our company specializes in importinginternationally advanced SPECTRO and OBLF direct reading spectrometers from Germamy.Wthin one minute, data on 22 chemical elements in molten steel can be obtained to ensure theachievement ofthe optimal chemical composition standard.

-

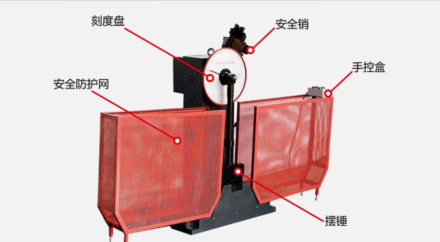

Test Equipment

Testing is the most effective process for gualily control, but product quality is definitely not detected. butmanufactured. The pursuit of hiah-auality products is our eternal theme. So our company is eauipped withhigh-end testing equipment to ensure excellent product quality and compliance.

-

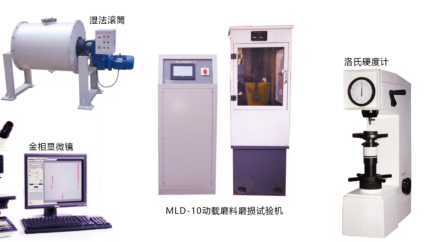

Test Equipment

Our company requires stict testing, sorting, cuting, and other processing for all incoming raw materials. Regarding product composition, hardness,toughness After more than a decade of continuous inspection, a scientiic product conrol testing curve has gradually been fomed,including metallographic structure, wear and fatigue resistance.

-

Raw material Detection

Our company uses a stock system for particle steel materials, with first in, first out and shorlage replenishment. Chemicalcomposiion testing of incoming steel materials,Whether harmful substances such as sulfur and phosphorus exceed the standardcan serve as a reference for ingredient preparaion in later produclion. The raw materials are rejected from entering the factory dueto defects such as rust, water stains, and oil stains.

-

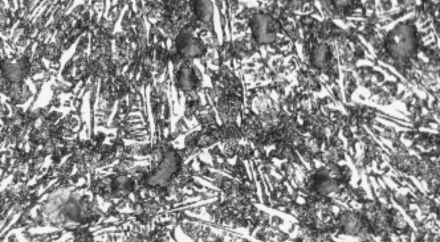

Microstructure

The metallographic microstructure of CADl cast iron grinding ball: carbon rich austenite+acicular ferrite+graphite bal.

-

Temperature Detection

The discharge temperature, pouring temperature, and heat treatment temperature are combined with real-timemonitoring and dynamic detection to calibrate each other, prevent errors, and ensure stable and consistentproduct performance.

Corporate Honors