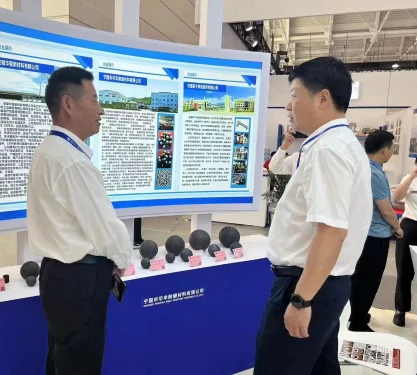

Who We are & What We Do

Ningguo Huafeng Wear-resistant Mlaterial Co., Ltd. is a professional wear-resistant material technology enterprise integrating R&D, production and sales.Ningguo Huafeng Wear-resistant Material Co., Ltd. has been focusing on wear-resistant material industy for more than 20 yearsand has the production capacity of 100,000 tons of wear-resistant casting balls and 10,000 tons of wear-resistant casting and forging.

Service

Products

Factory

Ningguo Huafeng Wear-resistant Material Co., Ltd. is a professional wear-resistant material technology enterprise integrating R&D, production and sales.

LEARN MORE

The "Austrian body ball wear resistant cast iron ball (2Q-CADl)" developed by the Anhui Provincial Science and TechnologyDepartment was certifed as "high-tech products". it is the first in the process industry and has been recognized by many largemining enterprises. It has achieved outstanding results in energy saving, consumption reduction, efficiency increase andenvironmental protection.

LEARN MORE

Ningguo Huafeng Wear-resistant Material Co., Ltd. has been focusing on wear-resistant material industry for more than 20 years,and has the production capacity of 50.000 tons of wear-resistant casting balls and 10.000 tons of wear-resistant casing andforging.

LEARN MORE

Get Free Consultation

20 +

Working Experience

Ningguo Huafeng Wear-resistant Material Co., Ltd. has been focusing on wear-resistant material industry for more than 20 years

100000+

Production Capacity

Ningguo Huafeng Wear-resistant Material Co., Ltd. has the production capacity of 100,000 tons of wear-resistant casting balls.

100000+

Another Accessory

Ningguo Huafeng Wear-resistant Material Co., Ltd. has the production capacity of 100,000 tons of wear-resistant casting and forging.

Checkout What We Provide for Our Clients

Opportunists, chasing tuyere, Long-termist, through the cycle.We insist to do and the right thing hard, insist to do a long term.Through the economic cycle, the realization of socialism for a long time.

PRODUCTION LINE

Casting Ball Production Line

lron mold sand covered 10000 ton casting ball production line

- The 10000 automaic production line for ballcasting has high technological content,fast energy and eficiency improvement, accurate qually control,and stable safety index. From the process of mold operation, fipping, mold opening and closing, sand shooting, and temperature adjustment,All adopt CNC equipment control to achieve digital management process.

- Three 10000 casting ball production lines,Flexible transfomation of material specificationsEnsure customer orders,Complete on time and with quality and quantity.

We Can Provide You With Services

Testing is the most effective process for quality control, but product quality is definitely not detected, butmanufactured. The pursuit of high-qualitly products is our eternal theme. So our company is equipped withhigh-end testing equipment to ensure excellent product quality and compliance.

-

Assist in acceptance

According to the contract signed by both parties, deliver the goods in a timely and high-guality manner.

01

-

Debugging Instruction

We will provide free after-sales service after the equipment acceptance is completed and your company oficially enters producion.

02

-

Regular Retum Visit

The service content includes (but is not limited to): responding to your information inguiries: Provide you with thenecessary spare parts and accessories at any time (for sale);

03

Company Warehouse Display

Our company has 5 automated continuous push rod heat treatment quenchingtempering production lines and 2 trolley type heat treatment furnaces. The dailyproduct processing capacity is nearly 300 tons, meeting the heat treatment needs ofproducts of different materials and specifcations, ensuring timely and efficient deliveryof customer orders, and maximizing customer satisfaction.

Discover Our Latest News And Insights !

25

Nov

Why Wholesale Alloyed Ball Solutions Matter for Industrial Grinding

In modern heavy industries, grinding efficiency directly influences profitability. Whether in mining, cement manufacturing, or power generation, the durability of each grinding media ball plays a crucial role in production stability. ...

LEARN MORE

12

Nov

Choosing the Right Grinding Media Ball for High-Efficiency Milling

In mineral processing, cement production, and thermal power plants, the performance of a grinding media ball often determines how efficiently a mill operates. While liner and mill design matter, the quality of the steel balls inside the...

LEARN MORE

10

Nov

Wholesale Grinding Steel Ball for Stable and Cost-Effective Milling